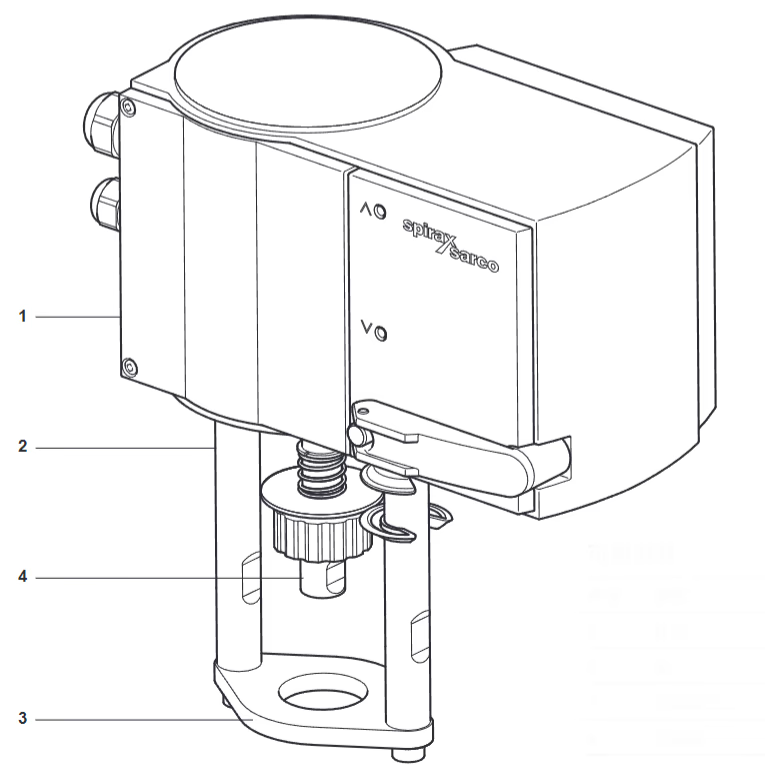

Product Overview

Spirax Sarco AEL3 Electric Linear Actuator is a stepper motor driven actuator specifically designed for Spira-trol series two-way control valves (DN15-DN50) and QL series three-way valves (DN15-DN50), enabling on/off control, modulating control, or special control functions. This product is suitable for chilled water, hot water, steam, or air media systems, with typical applications including HVAC systems and other industrial fluid control applications.

The actuator features a maintenance-free gearbox design with three fail-safe mode options: spring extend (AEL3E), spring retract (AEL3R), and non-spring (AEL3X) to meet different safety requirements. Standard power supply is 24Vac/dc, with optional 230Vac or 100-110Vac power modules available for specific applications. Control signals support VMD (Valve Motor Drive), 4-20mA analog signal, and 0-10Vdc analog signal; the 24Vac/dc version can also be expanded with a signal module for 2-10Vdc control. The actuator is equipped with three speed adjustment options, configurable via DIP switches to adapt to different response requirements.

Technical Specifications

Basic Parameters

| Parameter | Specification |

|---|---|

| Power Supply | Standard: 24Vac/dc (±15%); Optional: 230Vac, 100-110Vac (Requires Power Module) |

| Power Frequency | 50Hz/60Hz/Continuous |

| Power Consumption | 24Vac/dc: 12W; 230Vac/100-110Vac: 28VA |

| Control Signal | Standard: VMD, 4-20mA, 0-10Vdc; Extended: 2-10Vdc (24Vac/dc + Signal Module Only) |

| Feedback Signal | 0-10Vdc (Load >2500 ohms) |

| Actuator Speed | 0.5mm/s (2s/mm), 0.25mm/s (4s/mm), 0.16mm/s (6s/mm), DIP Switch Adjustable |

| Maximum Thrust | 2kN |

| Maximum Stroke | 20mm |

| Protection Rating | IP66 (EN60529) |

| Operating Temperature | -10℃~+55℃ |

| Storage Temperature | -20℃~+70℃ |

| Relative Humidity | <95% |

| Altitude | ≤2000m |

| Overvoltage Category | III |

| Pollution Degree | III |

| Spring Return Cycles | >40000 cycles |

| Status Indication | 2 LED lights (Status + Alarm) |

Certification Standards

| Certification Type | Related Standards |

|---|---|

| EMC Directive | 2014/30/EU, EN61000-6-2, EN61000-6-4 |

| LV Directive | 2014/35/EU, EN60730-1, EN60730-2-14 |

| Other Certifications | UL-UL873, cUL-CSA-C22.2 No.24-93 (Note: Not applicable to auxiliary limit switches, signal modules, and 230VAC/100-110VAC power modules) |

Maximum Differential Pressure (Class IV Shut-off, Spira-trol Metal Seat, Under-seat Flow)

| Actuator Model | Valve DN Size | PTFE Seat Max ΔP (bar) | Graphite Seat Max ΔP (bar) |

|---|---|---|---|

| AEL3E/AEL3R/AEL3X | DN15 | 40.0 | 40.0 |

| AEL3E/AEL3R/AEL3X | DN20 | 40.0 | 40.0 |

| AEL3E/AEL3R/AEL3X | DN25 | 39.1 | 31.2 |

| AEL3E/AEL3R/AEL3X | DN32 | 30.7 | 24.6 |

| AEL3E/AEL3R/AEL3X | DN40 | 11.5 | 8.8 |

| AEL3E/AEL3R/AEL3X | DN50 | 7.5 | 5.6 |

Maximum Differential Pressure (Class VI Shut-off, Spira-trol PTFE Soft Seat, Under-seat Flow)

| Actuator Model | Valve DN Size | PTFE Seat Max ΔP (bar) | Graphite Seat Max ΔP (bar) |

|---|---|---|---|

| AEL3E/AEL3R/AEL3X | DN15 | 40.0 | 40.0 |

| AEL3E/AEL3R/AEL3X | DN20 | 40.0 | 40.0 |

| AEL3E/AEL3R/AEL3X | DN25 | 40.0 | 38.5 |

| AEL3E/AEL3R/AEL3X | DN32 | 35.5 | 29.4 |

| AEL3E/AEL3R/AEL3X | DN40 | 14.6 | 12.0 |

| AEL3E/AEL3R/AEL3X | DN50 | 10.2 | 8.3 |

Material Specifications

| Component | Material |

|---|---|

| Housing | Polycarbonate |

| Yoke | Stainless Steel |

| Mounting Flange | Stainless Steel |

| Adapter | Stainless Steel |

Dimensions and Weight

Weight Parameters

| Product Model/Component | Weight (kg) |

|---|---|

| AEL3E/AEL3R | 5.7 |

| AEL3X | 4.2 |

| 180℃ High Temp Kit | 0.4 |

| 240℃ High Temp Kit | 0.7 |

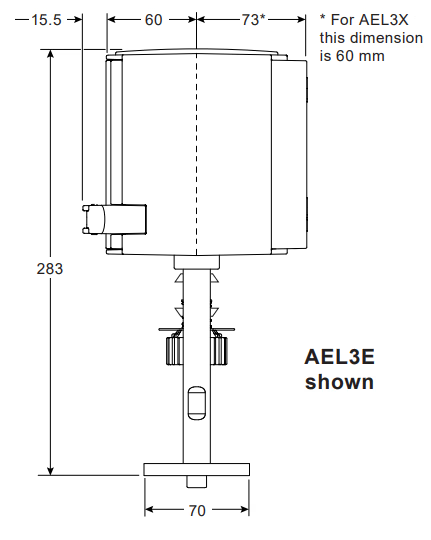

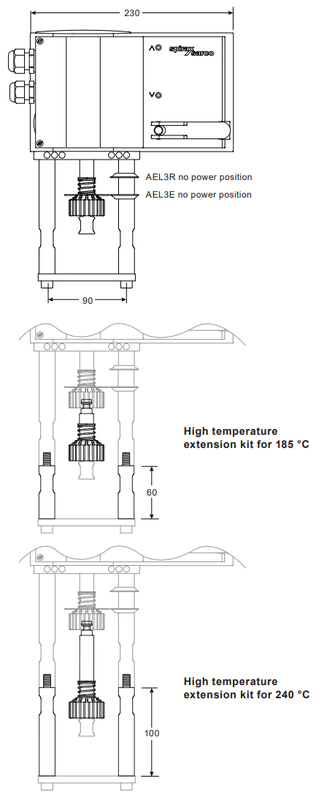

Overall Dimensions (Approximate, Unit: mm)

| Component | Dimension Details |

|---|---|

| AEL3E/AEL3R Length | 283 |

| AEL3X Length | 230 |

| High Temp Kit (180℃) Length | 60 |

| High Temp Kit (240℃) Length | 90 |

| Other Key Dimensions | 15.5, 60, 73, 70 (Refer to product drawings) |

Installation Instructions

Pre-Installation Requirements

Pre-Installation Notice

- Installation, commissioning, and maintenance must be performed by qualified professionals in strict compliance with this guide and relevant safety standards.

- Installation location must ensure actuator ambient temperature of -10℃~+55℃, relative humidity <95%, with sufficient space for cover removal (recommended ≥150mm).

- Disconnect power before installation, ensure system pressure is isolated or fully vented, and implement double isolation (double block and bleed) if necessary.

- Avoid installation in explosive atmospheres, oxygen-deficient spaces, extreme temperatures, or other hazardous environments. The actuator is not suitable for explosive atmospheres as defined by ATEX Directive 2014/34/EU.

Valve Installation Steps

Installation on Spira-trol Two-Way Control Valve

- Remove the actuator retaining nut from the valve.

- Screw the stem lock nut to a depth of 2 times the stem diameter.

- Screw the adapter onto the stem and tighten the lock nut.

- Compress the collet upward until a click confirms locking.

- Pull out the actuator handle, rotate counterclockwise to fully retract the stem, and keep the handle tilted to hold the retracted position.

- Place the mounting flange and actuator onto the bonnet.

- Reinstall and tighten the actuator retaining nut.

- For AEL3R/AEL3X: Extend the actuator stem via the handle until the collet is secured on the adapter; For AEL3E: Return the handle to position, the stem will extend automatically.

- Confirm the handle is fully returned to its original position. Do not power the actuator during installation.

Installation on QL Three-Way Valve

- Remove the actuator retaining nut from the valve.

- Screw the stem lock nut to a depth of 2 times the stem diameter.

- Pull out the actuator handle to fully retract the stem and keep it tilted.

- Screw the adapter onto the stem and tighten the lock nut.

- Ensure the adapter is installed on the bonnet thread (adapter not supplied with actuator).

- Place the mounting flange and actuator onto the bonnet thread/adapter.

- Reinstall and tighten the actuator retaining nut.

- Compress the collet upward until a click confirms locking.

- Extend the actuator stem via the handle until the collet is secured on the adapter.

- Confirm the handle is fully returned to its original position.

Wiring Requirements

Wiring Standards

- Read safety information before wiring. Personnel must be qualified for high voltage work.

- Install slow-blow fuses on all phase conductors except the ground wire.

- Internal protective ground conductor must be connected to the installation protective grounding system, and system integrity must not be compromised by disconnection of other equipment.

- If power wiring is exposed in accessible locations, use double-insulated 1.5mm² conductors as specified by IEC 60364 (or equivalent), increasing cross-section as appropriate for conductor length.

- Properly size the supply line safety transformer to avoid excessive voltage drop from inrush current.

- Wiring must comply with IEC60364 or equivalent standards. Fuses must not be installed in protective ground conductors.

- Installation location must have a disconnect switch, located near the actuator and easily accessible, clearly marked, must not disconnect the ground conductor, and comply with EN 60947-1 and EN 60947-3 or equivalent standards.

Different Control Mode Wiring

24V VMD Control Wiring

- AEL3E/AEL3R: Supports 2pt (on/off) and 3pt (modulating) control, power connected to 24Vac/dc, corresponding terminals T, X, 21, 1, 2a, 2b, 3u, 3i, 44.

- AEL3X: Supports 2pt (on/off) and 3pt (modulating) control, power connected to 24Vac/dc, corresponding terminals T, 21, 1, 2a, 2b, 3u, 3i, 44.

24V 4-20mA or 0-10V Signal Control Wiring

- Supports direct and reverse action switching by changing 2a and 2b wiring.

- 0% state corresponds to: 0V (0-10V signal), 4mA (4-20mA signal); 100% state corresponds to: 10V (0-10V signal), 20mA (4-20mA signal).

- Terminals 3u, 3i, 44 correspond to signal input interfaces. Refer to product wiring diagram for specific connections.

Wiring with Power Module (230V/100-110V)

- VMD Control: Power connected to L, N terminals, corresponding terminals 21, N, 2a, 2b, power converted through power module.

- 4-20mA/0-10V Signal Control: Supports direct/reverse action switching, power connected to L, N terminals, signal terminals 3u, 3i, 44 connected accordingly. Refer to wiring diagram.

Optional Component Installation

Power Module Installation (230VAC/100-110VAC)

Installation Steps

- Open the actuator cover and install the matching power module in the reserved space.

- Replace/cover the original 24V wiring label inside the actuator with the new power module label.

- Apply the corresponding power module marking label on the existing label at the bottom of the housing, covering the original 24V and UL markings.

Caution

This power module is not compatible with the 2-10V signal module.

Power Module Removal

Removal Steps

- Ensure the actuator is completely disconnected from power.

- Remove all wiring.

- Insert a flat-head screwdriver into the power module slot, press down and gently push right to unlock the latch (be careful not to break it).

- Gently pry open and remove the power module.

High Temperature Kit Installation (130℃~240℃)

Installation Steps

- Loosen the actuator fixing screws on the mounting flange side.

- Connect the extension rod to the actuator post, tightening torque 12Nm.

- Connect the mounting flange to the extension post, tightening torque 25Nm.

- Install the matching extension collet onto the existing collet and secure.

Note

High temperature kits are available in two types: for 130℃~180℃ and 180℃~240℃ applications.

2-10Vdc Signal Module Installation

Installation Steps

- Only applicable to 24Vac/dc powered actuators, not compatible with 230VAC/100-110VAC power modules.

- Follow module installation guide to secure the module. Wiring terminals 1, 2, 3 correspond to signal inputs. Refer to product wiring diagram.

- After installation, cover original labels with new labels. This module is not UL certified.

Auxiliary Limit Switch Installation

Installation Steps

- Secure the limit switch according to product installation drawings. Terminals S1, S2 are limit signal interfaces.

- After installation, cover original labels with new labels. This component is not UL certified.

- Compatible ambient temperature: -10℃~60℃, relative humidity 5-95%.

Commissioning

Automatic Commissioning

Commissioning Process

- When the actuator is powered for the first time, it automatically starts the commissioning program, with both LED lights flashing red.

- Commissioning process: The actuator stem first fully extends to mechanical stop, then fully retracts to mechanical stop.

- After commissioning, the actuator automatically stops at the position corresponding to the control signal.

Manual Commissioning

Commissioning Method

- Fold the actuator handle twice within 4 seconds to start manual commissioning (refer to product diagram).

- During commissioning, fold the handle once to stop commissioning.

LED Status Indication

| LED Status | Indication |

|---|---|

| Both lights flashing red simultaneously | Commissioning in progress |

Maintenance

Maintenance Guidelines

- Before any maintenance operation, ensure the actuator is disconnected from power, system is depressurized and cooled to room temperature.

- The actuator has no internal components requiring maintenance. Daily maintenance focuses on external connections and installation status.

- Regularly check wiring terminals for looseness or corrosion, ensure grounding system is intact.

- Check actuator housing for damage, ensure IP66 protection rating is not compromised.

- Use only Spirax Sarco original replacement parts for maintenance. Non-original parts are prohibited.

- If the actuator is idle for extended periods, store in a dry, ventilated environment, avoiding moisture and extreme temperatures.

- For products that cannot self-drain, implement freeze protection measures to avoid damage from exposure to sub-freezing temperatures.

Safety Precautions

Safety Warning

- Installation, commissioning, and maintenance must be performed by qualified professionals in strict compliance with operating instructions and relevant safety standards.

- Improper installation or unauthorized use may result in personal injury, equipment damage, or actuator performance abnormalities.

- Confirm correct wiring before powering on. Disconnect power before opening the actuator cover.

- The actuator is designed for Installation Category II, relying on overvoltage protection and basic protective installation. Do not modify protection configuration.

- Product exterior surface may be hot during normal use, with surface temperature up to 90℃ (194℉) under maximum operating conditions. Avoid direct contact.

- Do not use cellular/mobile phones within 1 meter of the actuator or its wiring to avoid electromagnetic interference. If near radio transmitters or if main power has strong electrical noise, install power line protection devices (filtering, conditioning, voltage regulation, peak suppression).

- The actuator is not suitable for use as a safety device and must not be used in safety-related applications as defined by Pressure Equipment Directive 2014/68/EU or Machinery Directive 2006/42/EU.

- Assess risks when manually handling heavy actuators. Avoid manual handling that may cause back or body injury. Use lifting equipment when necessary.

- Work area must have safe access, adequate lighting, and safety work platforms and protective equipment when necessary.

- When returning products, provide written product hazard information and safety data sheets in accordance with EU health, safety, and environmental laws.

Product Naming Convention

| Code | Description |

|---|---|

| A | Actuator |

| E | Electric Type |

| L | Linear Action |

| 3 | Series Number |

| Fail Mode | E=Spring Extend, R=Spring Retract, X=Non-Spring |

| Thrust | 2=2kN |

| Stroke | 20=20mm |

| Max Speed | 2s/mm=0.5mm/s, 4s/mm=0.25mm/s, 6s/mm=0.16mm/s (DIP Switch Adjustable) |

| Power | 24Vac/dc (Standard), 230Vac/100-110Vac (Requires Power Module) |

| Control Signal | 24-230V VMD, 0-10Vdc, 4-20mA; 2-10Vdc (Requires Signal Module, 24Vac/dc Only) |

Selection and Ordering

Selection Guidelines

Selection Recommendations

- Select model based on valve type (Spira-trol two-way valve/QL three-way valve) and DN size.

- Determine fail-safe mode requirement: Spring Extend (E), Spring Retract (R), or Non-Spring (X).

- Select power type based on supply conditions: 24Vac/dc (standard) or 230Vac/100-110Vac (requires power module).

- Select signal type based on control requirements: VMD, 4-20mA, 0-10Vdc, or 2-10Vdc (requires signal module).

- If media temperature exceeds 130℃, select corresponding high temperature kit (180℃ or 240℃).

- Confirm system maximum differential pressure does not exceed actuator's valve shut-off differential pressure limit.

Ordering Examples

Examples

- 1 set AEL3E 24Vac/dc electric actuator + 1 set 180℃ high temperature kit

- 1 set AEL3R 230Vac electric actuator (with power module) + 1 set auxiliary limit switch

- 1 set AEL3X 100-110Vac electric actuator (with power module) + 2-10V signal module

Related Products

Explore similar products in our catalog