Spirax Sarco SV615 is a full-lift, full-nozzle safety valve designed for steam, air, non-reactive industrial gases and non-hazardous liquids. It complies with EN ISO 4126:2004 and other major international standards, and offers a wide range of port sizes, connection types and sealing options to provide reliable pressure protection for process equipment.

Spirax Sarco SV615 safety valve is a full-lift, full-nozzle pressure protection device designed for use with steam, air, non-reactive industrial gases and non-hazardous liquids. It fully complies with EN ISO 4126:2004, is certified to the European Pressure Equipment Directive (PED) 97/23/EC, and its seat tightness meets ANSI/API STD 527-1992. The SV615 provides reliable overpressure protection for boilers, pressure vessels, air receivers, air compressors and other pressurised equipment.

The SV615 range offers extensive configuration options, including a wide selection of port sizes, connection types, sealing materials and surface finishes, so that sanitary, appearance and temperature/pressure requirements in different applications can be met. Each valve is supplied as standard with an EN 10204 2.2 test certificate, and an EN 10204 3.1 material certificate is available on request.

| Item | Specification |

|---|---|

| Set pressure | Minimum 0.3 bar g; 1/2"–1 1/4" models maximum 18 bar g; 1 1/2"–2" models maximum 14 bar g |

| Overpressure | Steam 5%; gas 10%; liquid 10–25% |

| Maximum allowable backpressure | Steam 5%; gas 10%; liquid 10–25% |

| Blowdown | Steam / gas 10%; liquid 2.5–20% |

| Cold hydraulic test pressure | 37.5 bar g |

| Temperature range | Metal seat: -90℃ to +230℃; Nitrile (NBR) soft seal: -30℃ to +120℃; EPDM soft seal: -50℃ to +150℃; Fluoroelastomer soft seal: -20℃ to +200℃ (Note: soft seals must not be used on steam.) |

| Orifice DN | Flow area (mm²) | Saturated steam discharge (kg/h, 10 bar g) | Air discharge (l/s, 10 bar g) | Water discharge (kg/h, 10 bar g) | Hot water discharge (kW, 10 bar g) |

|---|---|---|---|---|---|

| 15/20 | 113 | 501 | 186 | 9 912 | 231.98 |

| 20/32 | 314 | 1 393 | 517 | 27 544 | 644.63 |

| 25/40 | 452 | 2 005 | 744 | 39 649 | 927.94 |

| 32/50 | 661 | 2 933 | 1 088 | 57 982 | 1 356.96 |

| 40/65 | 1 075 | 4 769 | 1 770 | 94 297 | 2 206.92 |

| 50/80 | 1 662 | 7 374 | 2 736 | 145 788 | 3 411.96 |

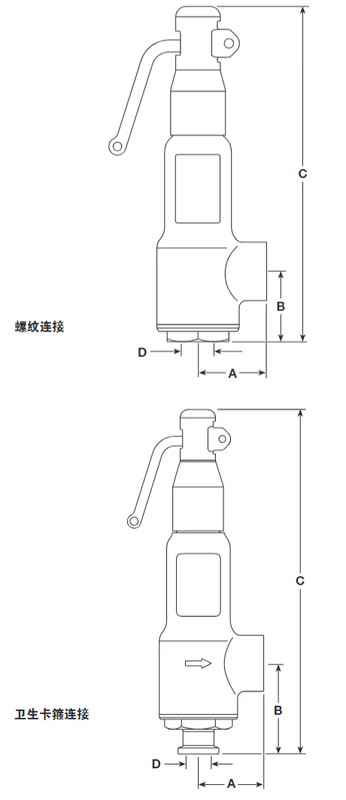

| Port size DN | Inlet | Outlet | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Flow diameter Ø (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| 15 | 1/2" | 3/4" | 40 | 40 | 194 | 12 | 1.3 |

| 20 | 3/4" | 1 1/4" | 55 | 44 | 229 | 20 | 2.4 |

| 25 | 1" | 1 1/2" | 60 | 48 | 242 | 24 | 2.9 |

| 32 | 1 1/4" | 2" | 70 | 58 | 279 | 29 | 4.2 |

| 40 | 1 1/2" | 2 1/2" | 81 | 67 | 365 | 37 | 8.8 |

| 50 | 2" | 3" | 96 | 80 | 420 | 46 | 13.0 |

| Port size DN | Inlet | Outlet | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Flow diameter Ø (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| 15 | 1/2" | 3/4" | 40 | 55 | 209 | 12 | 1.4 |

| 20 | 1" | 1 1/4" | 55 | 60 | 245 | 20 | 2.6 |

| 25 | 1" | 1 1/2" | 60 | 64 | 258 | 24 | 3.1 |

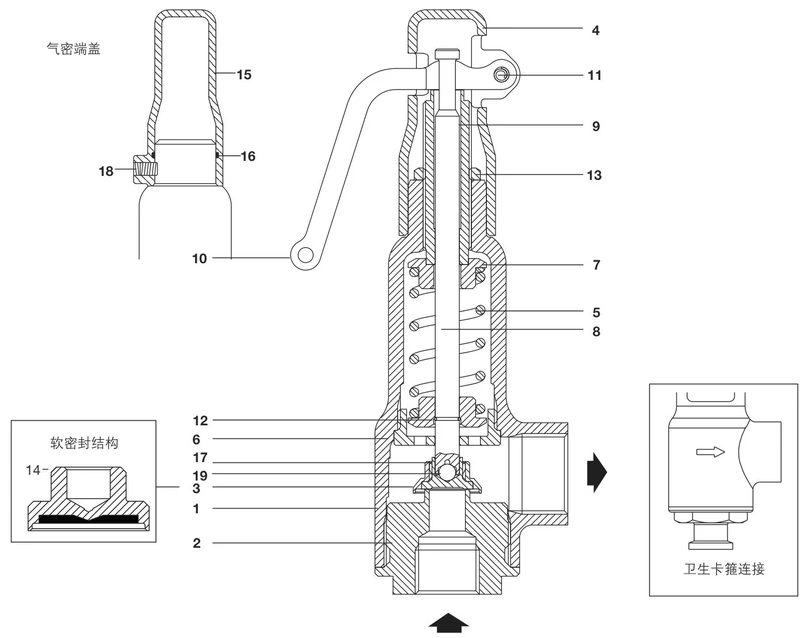

| No. | Component name | Specification / description | Material standard |

|---|---|---|---|

| 1 | Body | General | Bronze (BS EN 1982 CC491KM) |

| 2 | Nozzle | DN15 / DN20 | Stainless steel (BS 970 431 S29) |

| 2 | Nozzle | DN25–DN50 | Stainless steel (BS 3146 Pt2 Gr. ANC2) |

| 2 | Nozzle | Clamp connection | Stainless steel (ASTM A276 316L) |

| 3 | Disc | General | Stainless steel (ASTM A276 316L) |

| 4 | Huddling chamber | General | Bronze (BS EN 1982 CC491KM) |

| 5 | Spring | General | Chrome vanadium alloy steel (BS 2803 735 A50 HS) |

| 6 | Spindle guide | General | Brass (BS 2872 CZ 121) |

| 7 | Spring plate | General | Brass (BS 2872 CZ 121) |

| 8 | Spindle | General | Stainless steel (BS 970 431 S29) |

| 9 | Adjusting screw | General | Brass (BS 2874 CZ 121) |

| 10 | Lever hood | General | Ductile iron (zinc plated) |

| 11 | Pivot pin | General | Stainless steel (AISI 304) |

| 12 | Circlip | General | Stainless steel (BS 2056 316 S42) |

| 13 | Adjusting lever locknut | General | Brass (BS 2872 CZ 121) |

| 14 | Soft seat disc | Nitrile material | Stainless steel / ASTM A276 316 + nitrile |

| 14 | Soft seat disc | EPDM material | Stainless steel / ASTM A276 316 + EPDM |

| 14 | Soft seat disc | Fluoroelastomer material | Stainless steel / ASTM A276 316 + fluoroelastomer |

| 15 | Blind cap | General | Bronze (BS EN 1982 CC491KM) |

| 16 | Cap seal | General | Nitrile rubber |

| 17 | Collar | General | Brass (BS 2874 CZ 121) |

| 18 | Setting screw | General | Steel |

| 19 | Ball | General | Stainless steel |

The product model can be configured using the following codes:

Spirax Sarco SV615AS DN15 BSP threaded safety valve, set pressure 6 bar g, with electroless nickel plated polished finish (add “P”).

Explore similar products in our catalog