Product Overview

Spirax Sarco DCV1 disc check valve uses a flange wafer-mounted installation method, specifically designed for process pipelines, hot water systems, steam and condensate systems, and can be adapted to various fluids such as oil, air, gases, and water. The product flange spacing complies with EN558 Part1 Series 49 standard, certified by ISO 9001 and meets European Pressure Equipment Directive 97/23/EC requirements, featuring compact structure and excellent sealing performance. Note that this wafer-mounted check valve is not suitable for applications with severe pulsation such as compressor outlets.

Core Configuration and Selection

Seat Material Selection

- Standard Configuration: Metal seat, suitable for steam systems

- Optional Configuration: Fluorinated rubber (Viton) soft seat (suitable for oil, gas, air systems); EPDM soft seat (suitable for water systems)

Spring Configuration Selection

- Standard Spring: Austenitic stainless steel (BS 2056 316 S42), general purpose for normal conditions

- Heavy Duty Spring: Austenitic stainless steel (BS 2056 316 S42), opening pressure 700 mbar, suitable for boiler feed water applications (maximum port size DN65)

- No Spring Option: Suitable for low opening pressure requirements, must be installed on vertical pipelines with flow direction from bottom to top

Sealing Standard Selection

- Standard Configuration: Compliant with DIN 3230 part 3 BN2 standard

- Optional Configuration: Compliant with DIN 3230 part 3 B03 standard (must be specified in advance)

- Soft Seat Characteristic: Can meet DIN 3230 part 3 BN1 and B01 standards when there is a pressure differential

Technical Parameter Details

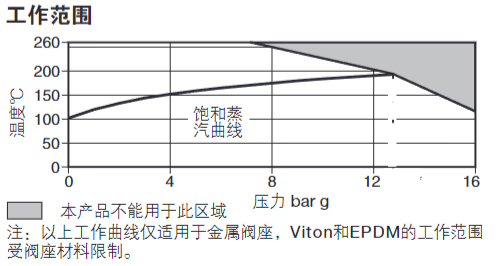

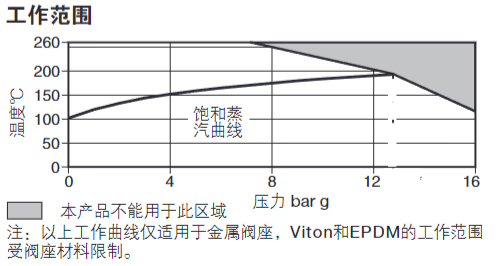

Operating Range Limits

- Maximum Operating Pressure (PMO): 13.2 bar g @ 196℃

- Maximum Operating Temperature (TMO): 260℃ @ 7 bar g

- Seat Temperature Limits: Fluorinated rubber seat -15℃~+250℃; EPDM seat -50℃~+150℃

- Special Note: Metal seat operating curve applies only to itself, soft seat operating range is limited by material

Opening Pressure (Zero Flow Condition)

| DN Port Size | Standard Spring Opening Pressure (mbar) | No Spring Opening Pressure (mbar) | Heavy Duty Spring Opening Pressure (mbar) |

|---|

| 15 | 25 | 20 | 700 |

| 20 | 25 | 20 | 700 |

| 25 | 25 | 20 | 700 |

| 32 | 27 | 20 | 700 |

| 40 | 28 | 20 | 700 |

| 50 | 29 | 20 | 700 |

| 65 | 30 | 20 | 700 |

| 80 | 31 | 20 | - |

| 100 | 33 | 20 | - |

Kv Value (Flow Coefficient)

| DN Port Size | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|

| Kv Value | 4.4 | 6.8 | 10.8 | 17 | 26 | 43 | 60 | 80 | 113 |

- Imperial CV (UK): CV(UK) = Kv × 0.963

- US CV (US): CV(US) = Kv × 1.156

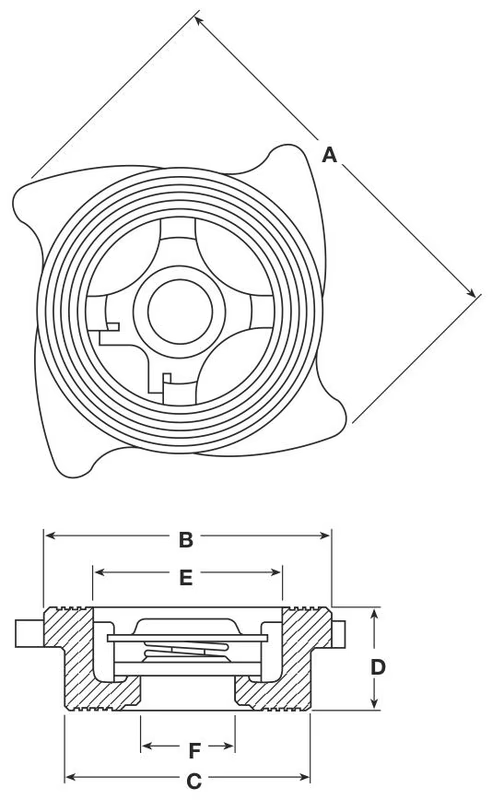

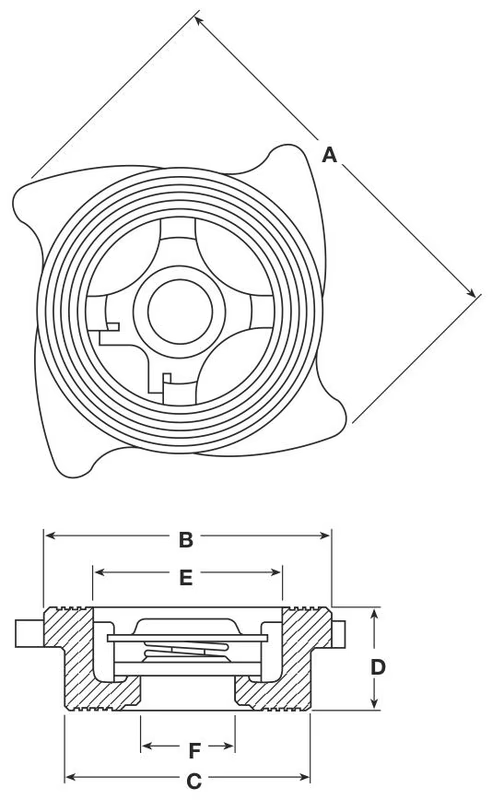

Dimensions and Weight (Approximate)

| Port Size (DN) | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Dimension D (mm) | Dimension E (mm) | Dimension F (mm) | Weight (kg) |

|---|

| 15 | 60.0 | 43 | 38 | 16.0 | 29.0 | 15 | 0.13 |

| 20 | 69.5 | 53 | 45 | 19.0 | 35.7 | 20 | 0.19 |

| 25 | 80.5 | 63 | 55 | 22.0 | 44.0 | 25 | 0.32 |

| 32 | 90.5 | 75 | 68 | 28.0 | 54.5 | 32 | 0.55 |

| 40 | 101.0 | 85 | 79 | 31.5 | 65.5 | 40 | 0.74 |

| 50 | 115.0 | 95 | 93 | 40.0 | 77.0 | 50 | 1.25 |

| 65 | 142.0 | 115 | 113 | 46.0 | 97.5 | 65 | 1.87 |

| 80 | 154.0 | 133 | 128 | 50.0 | 111.5 | 80 | 2.42 |

| 100 | 184.0 | 154 | 148 | 60.0 | 130.0 | 100 | 3.81 |

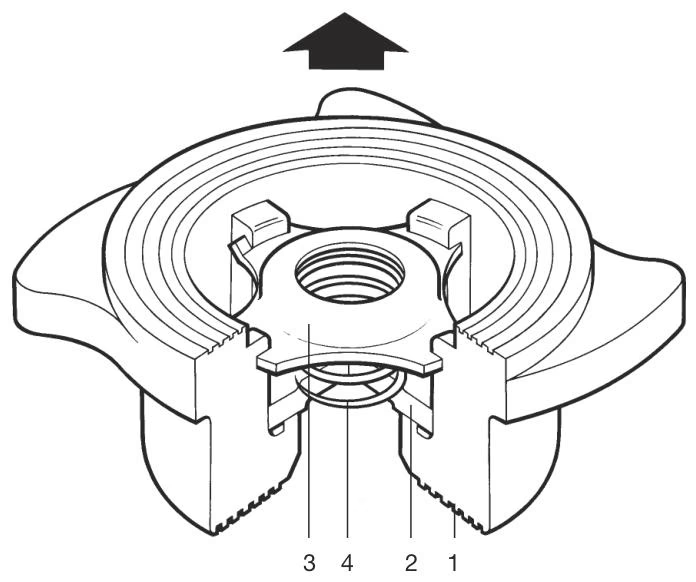

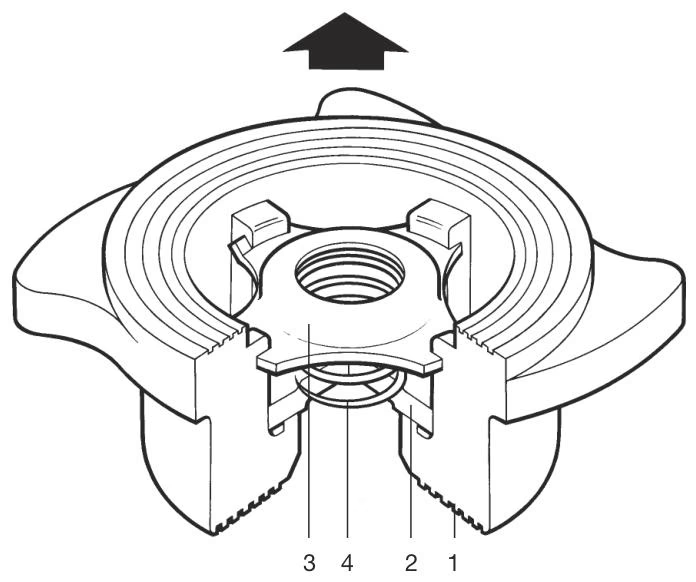

Component Material Details

| No. | Component Name | Material Specification | Standard |

|---|

| 1 | Body | Bronze | WS 2.1050 |

| 2 | Disc | Austenitic Stainless Steel | ASTM A276 316 |

| 3 | Spring Retainer | Austenitic Stainless Steel | BS 1449 316 S11 |

| 4 | Standard Spring | Austenitic Stainless Steel | BS 2056 316 S42 |

| 5 | Heavy Duty Spring | Austenitic Stainless Steel | BS 2056 316 S42 |

Installation and Maintenance

Installation Requirements

- Install according to the flow direction arrow on the valve body. Valves with springs can be installed in any orientation

- Valves without springs must be installed on vertical pipelines with flow direction from bottom to top

- Utilize the valve body "cam" design to adapt to different flanges, rotate the valve body to contact the bolts, ensuring the valve is centered in the pipeline

- Flanges, bolts, nuts, and gaskets must be provided by the installer

- Strictly prohibited for applications with severe pulsation such as compressor outlets

| Item | Details |

|---|

| Spare Parts Provision | No spare parts provided |

| Maintenance Property | Non-repairable product |

| Reference Document | Installation and Maintenance Guide (IM-P134-07) |

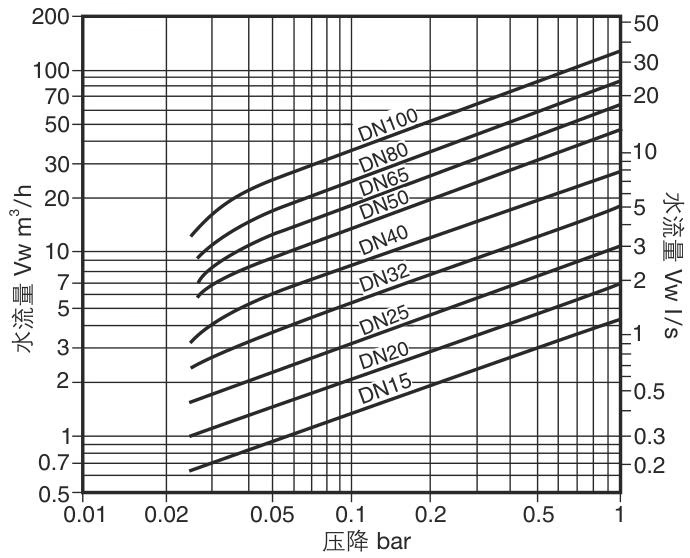

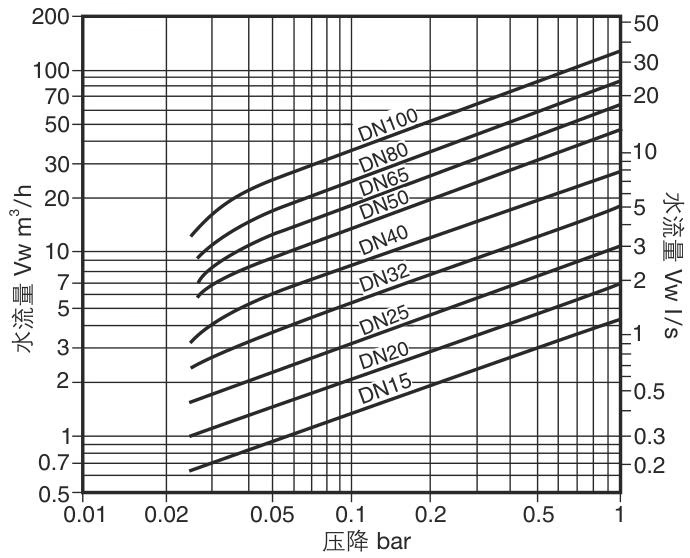

Pressure Loss Calculation

Basic Description

- Pressure loss chart is based on 20℃ water tests, applicable to horizontally installed spring-loaded check valves

- Vertical flow conditions only show minor deviations when partially open, other fluids require calculation of equivalent water flow rate

Ordering Marking Meanings

- No Marking: Standard spring + metal disc configuration

- Special Configuration: Must clearly specify seat material (metal/Viton/EPDM), spring type (standard/heavy duty/no spring), and sealing standard (BN2/B03)

Ordering Example

Spirax Sarco DN50 DCV1 check valve, EN1092 PN25 flange connection (must specify seat, spring, and sealing standard requirements)

- Standard Provision: Product "Test Report"

- Additional Requirements: Must be specified when ordering, can provide corresponding material or performance certificates

Safety and Disposal

- Fluorinated rubber (Viton) components may decompose to produce hydrofluoric acid when approaching 315℃ and above

- Avoid skin contact and inhalation of hydrofluoric acid to prevent skin burns and respiratory damage

- Fluorinated rubber should be disposed of according to the recommended method in the Installation and Maintenance Guide (IM-P134-07). Proper disposal poses no environmental hazard

- For pressure loss values of other gases such as steam and compressed air, please consult Spirax Sarco