Spirax Sarco S1 Baffle Type Separator, manufactured from ductile iron, compliant with European Pressure Equipment Directive 97/23/EC. Designed to remove droplets from steam, compressed air or gas systems, optional insulating jacket improves performance, supports ½", ¾" and 1" BSP/NPT threaded connections, working pressure up to 13.8 bar g, working temperature range 0-200°C, easy installation and maintenance, recyclable with no ecological impact.

Spirax Sarco S1 Baffle Type Separator, manufactured from ductile iron, is designed to remove droplets from steam, compressed air or gas systems, ensuring stable system operation. The product can be equipped with an insulating jacket to effectively improve separation performance, meeting high-efficiency separation requirements in industrial applications. This product complies with European Pressure Equipment Directive 97/23/EC, reliable quality, test reports available (certificate must be specified when ordering).

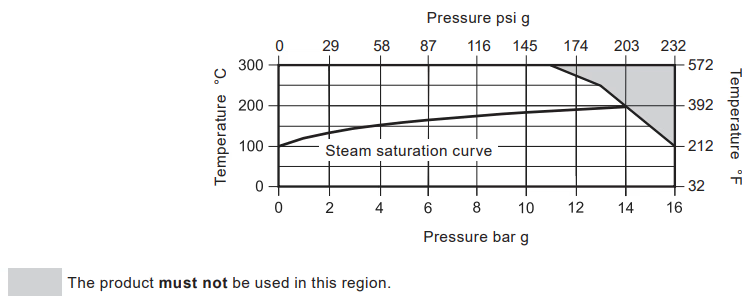

| Parameter | Value |

|---|---|

| Body Design | PN16 |

| PMA Max. Allowable Pressure | 16 bar g @ 100°C |

| TMA Max. Allowable Temperature | 300°C @ 11 bar g |

| Min. Allowable Temperature | 0°C |

| PMO Max. Working Pressure | 13.8 bar g |

| TMO Max. Working Temperature | 200°C @ 13.8 bar g |

| Min. Working Temperature | 0°C |

| Design Max. Cold Hydraulic Test Pressure | 24 bar g |

Note

Minimum allowable temperature is 0°C, consult Spirax Sarco for lower temperatures.

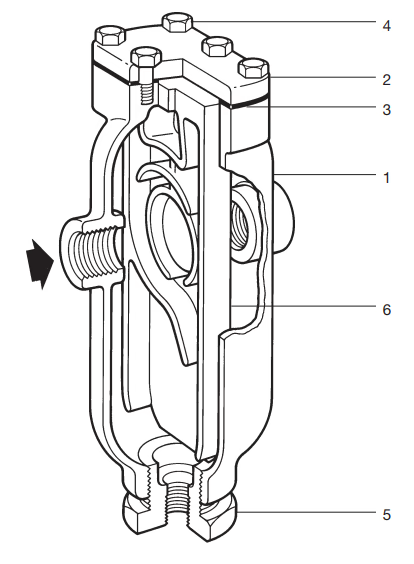

| No. | Part | Size | Material | Standard |

|---|---|---|---|---|

| 1 | Body | - | Ductile Iron | DIN 1693 Gr.GGG 40 |

| 2 | Cover | - | Ductile Iron | DIN 1693 Gr.GGG 40 |

| 3 | Gasket | - | Laminated Graphite | - |

| 4 | Bolts | - | Steel | BS1768 Gr 5 |

| 5 | Bush | ½", ¾" | Steel | - |

| 5 | Bush | 1" | Steel | ASTM A105 |

| 6 | Baffle | - | Cast Iron | DIN 1691 Gr. GG20 |

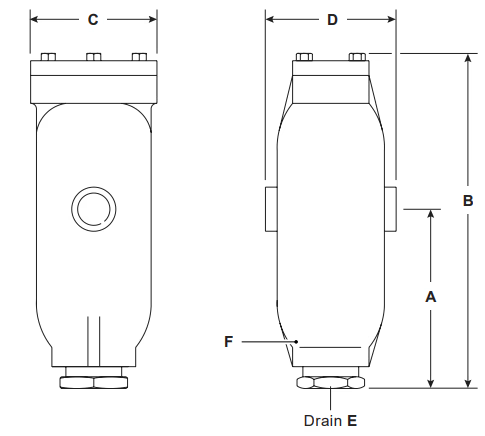

| Size | A | B | C | D | E (Drain) | F | Weight | Capacity |

|---|---|---|---|---|---|---|---|---|

| ½" | 124 | 225 | 86 | 88 | ½" | 1" | 2.7 kg | 0.53 L |

| ¾" | 156 | 260 | 110 | 113 | ½" | 1½" | 4.2 kg | 1.13 L |

| 1" | 222 | 377 | 143 | 152 | ½" | 2" | 8.1 kg | 3.15 L |

Note

Dimensions in mm, weights and capacities are approximate values.

Note

Drain outlet must be connected to a steam trap to ensure timely discharge of separated liquid, otherwise separation performance will be affected.

For detailed maintenance procedures, refer to the Installation and Maintenance Instructions (IM-P023-55) provided with the product. Contact Spirax Sarco professional team for technical support.

1-¾" BSP Spirax Sarco S1 Separator, Ductile Iron Body

This product can be recycled. Proper disposal according to standard procedures will not cause adverse environmental impact and meets environmental requirements.

Explore similar products in our catalog