Spirax Sarco APT14 series automatic steam trap pumps, PN16 pressure rating, steam-powered without electricity, support flange/threaded connections, capable of draining under vacuum conditions, automatically switching between trap and pump cycles, compatible with multiple standards, efficiently discharging condensate.

Spirax Sarco APT14, APT14HC, and APT14SHC automatic steam trap pumps are high-efficiency condensate discharge equipment powered by steam, with a pressure rating of PN16, operating without electricity. The device automatically switches between trap cycle and pump cycle based on pipeline pressure changes, reliably discharging condensate from process equipment under any operating conditions including vacuum, suitable for various industrial applications.

| Model | Body Material | Connection Type | Pump Displacement/Cycle | Discharge at 1m Installation Height + 5bar g Motive Steam + 1bar g Back Pressure |

|---|---|---|---|---|

| APT14 | Ductile Iron (EN JS 1025 or ASTM A395) | Threaded, Flange | 5L | Trap Mode: 4000kg/h; Pump Mode: 1100kg/h |

| APT14HC | Ductile Iron (EN JS 1025 or ASTM A395) | Flange | 8L | Trap Mode: 9000kg/h; Pump Mode: 2800kg/h |

| APT14SHC | Carbon Steel (EN 1.0619 or ASTM A216 WCB) | Flange | 8L | Trap Mode: 9000kg/h; Pump Mode: 2800kg/h |

| Model | Body Material | Inlet and Outlet Port Sizes and Connection Type | Connection Standard | Motive Steam Inlet/Exhaust Port (Connection Type) | Motive Steam Inlet/Exhaust Port (Size) |

|---|---|---|---|---|---|

| APT14 | Ductile Iron | Flange Connection DN40 Inlet × DN25 Outlet | EN 1092 PN16 | BSP or NPT | DN15(½") |

| ANSI 150 B 16.5 | NPT | DN15(½") | |||

| JIS 10 (JIS B 2210) | BSP | DN15(½") | |||

| KS 10 (KS B 1511) | BSP | DN15(½") | |||

| APT14 | Ductile Iron | Threaded Connection 1½" Inlet × 1" Outlet | BSP (BS 21 parallel) | BSP | DN15(½") |

| NPT | NPT | DN15(½") | |||

| APT14HC | Ductile Iron | Flange Connection DN50 Inlet × DN40 Outlet | EN 1092 PN16 | BSP | DN15(½") |

| ANSI 150 B 16.5 | NPT | DN15(½") | |||

| JIS 10 (JIS B 2210) | BSP | DN15(½") | |||

| KS 10 (KS B 1511) | BSP | DN15(½") | |||

| APT14SHC | Carbon Steel | Flange Connection DN50 Inlet × DN40 Outlet | EN 1092 PN16 | BSP | DN15(½") |

| ANSI 150 B 16.5 | NPT | DN15(½") | |||

| JIS 10 (JIS B 2210) | BSP | DN15(½") | |||

| KS 10 (KS B 1511) | BSP | DN15(½") |

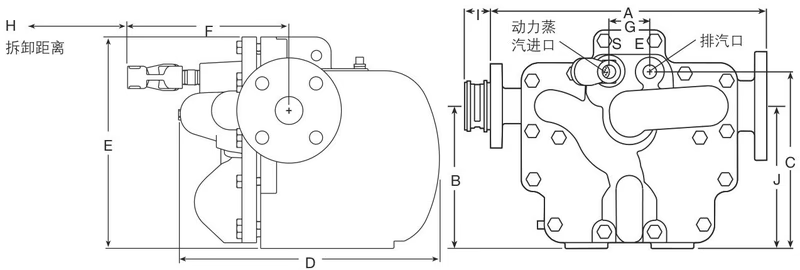

| Model | Connection Type | Dimension Parameters (mm) A | B | C | D | E | F | G | H | I (PN16) | I (ANSI) | J | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| APT14 | Threaded | 350 | 198 | 246 | 385 | 304 | 258 | 57 | 250 | - | - | 198 | 45 |

| APT14 | Flange | 389 | 198 | 246 | 385 | 304 | 258 | 57 | 250 | - | - | 198 | 45 |

| APT14HC | Flange | 476 | 198 | 270 | 400 | 335 | 261 | 57 | 275 | 31.5 | 45 | 198 | 65 |

| APT14SHC | Flange | 508 | 206 | 278 | 407 | 351 | 261 | 57 | 275 | 31.5 | 45 | 206 | 105 |

| Limit Item | Value |

|---|---|

| Maximum Motive Steam Inlet Pressure | 13.8 bar g |

| Maximum Allowable Pressure (PMA) | 16 bar g @ 120°C |

| Maximum Allowable Temperature (TMA) | 300°C @ 12.8 bar g |

| Minimum Allowable Temperature | -10°C (lower temperatures require consultation with manufacturer) |

| Maximum Operating Pressure for Saturated Steam (PMO) | 13.8 bar g @ 198°C |

| Maximum Back Pressure | 5 bar g |

| Maximum Operating Temperature for Saturated Steam (TMO) | 198°C @ 13.8 bar g |

| Ambient Temperature Range | -10°C - 200°C |

| Design Maximum Cold Water Test Pressure | 24 bar g |

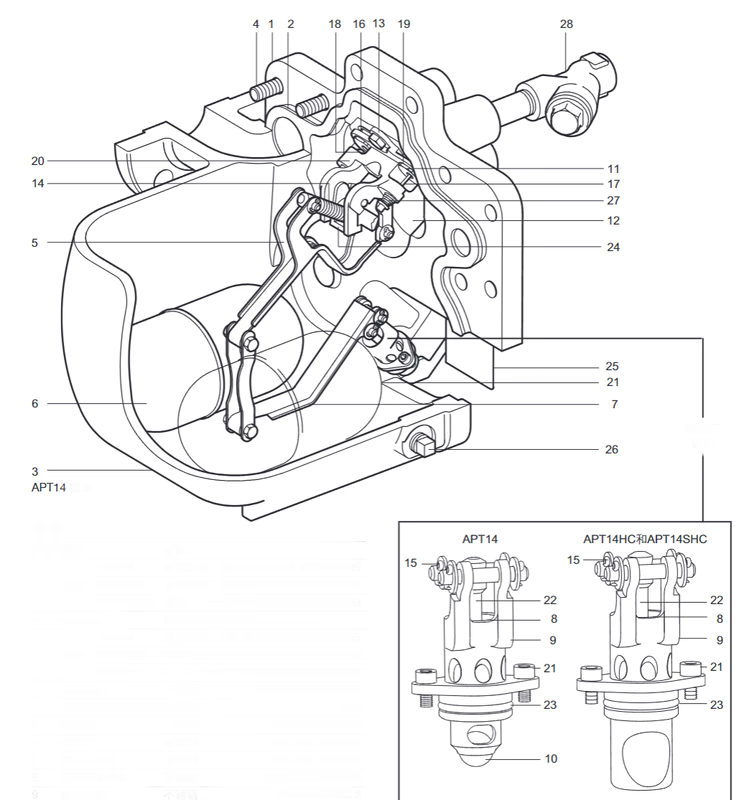

| No. | Component | Material Standard (Common) |

|---|---|---|

| 2 | Pump Cover Gasket | Laminated Graphite Stainless Steel Reinforced |

| 4 | Pump Cover Dowel Pin | Stainless Steel ISO 3506 Gr. A2 70 |

| 5 | Pump Link | Stainless Steel BS 1449 304 S15 |

| 6 | Float Ball | Stainless Steel BS 1449 304 S15 |

| 7 | Trap Link | Stainless Steel BS 1449 304 S15 |

| 8 | Second Stage Trap | Stainless Steel ASTM A276 440 B |

| 9 | Trap Chamber | Stainless Steel BS 3146 ANC 2 |

| 11 | Valve Seat (Inlet Check Valve) | Stainless Steel ANSI 420 |

| 12 | Baffle (Inlet Check Valve) | Stainless Steel BS 3146 ANC 4B |

| 13 | Pump Mechanism Bracket | Stainless Steel BS 3146 ANC 4B |

| 14 | Spring (Pump) | Stainless Steel BS 2056 302 S26 Gr. 2 |

| 15 | Split Pin | Stainless Steel BS 1574 |

| 16 | Exhaust Valve Seat | Stainless Steel BS 970 431 S29 or ASTM A276 431 |

| 17 | Inlet Valve Plug and Seat Assembly | Stainless Steel |

| 18 | Exhaust Valve Plug | Stainless Steel BS 3146 ANC 2 |

| 19 | Valve Seat Gasket | Stainless Steel BS 1449 409 S19 |

| 20 | Pump Mechanism Bolt | Stainless Steel ISO 3506 Gr. A2 70 |

| 21 | Trap Cover Bolt | Stainless Steel BS 6105 A4 80 |

| 22 | First Stage Trap | Stainless Steel BS 970 431 S29 or ASTM A276 431 |

| 23 | 'O' Ring | EPDM |

| 24 | Nameplate | Stainless Steel BS 3146 ANC 2 |

| 25 | Push Rod | Stainless Steel BS 1449 304 S16 |

| 26 | Exhaust Plug | Steel DIN 17440 1.4571 |

| 27 | Inlet Valve Spring | Stainless Steel |

| No. | Component | APT14 Material | APT14HC Material | APT14SHC Material |

|---|---|---|---|---|

| 1 | Pump Cover | Ductile Iron EN JS 1025 or ASTM A395 | Ductile Iron EN JS 1025 or ASTM A395 | Carbon Steel EN1.0619+H or ASTM A216 WCB |

| 3 | Pump Body | Ductile Iron EN JS 1025 or ASTM A395 | Ductile Iron EN JS 1025 or ASTM A395 | Carbon Steel EN1.0619+H or ASTM A216 WCB |

| 10 | Valve Plug (APT14) | Stainless Steel ASTM A276 440 B | - (not applicable) | - (not applicable) |

| 28 | Inlet Valve Filter | Ductile Iron | Ductile Iron | Carbon Steel |

| 29 | Check Valve DCV (APT14HC) | - (not applicable) | Stainless Steel (not shown) | - (not applicable) |

| Model | Pump Displacement/Cycle | At 1m Installation Height + 5bar g Motive Steam + 1bar g Back Pressure |

|---|---|---|

| APT14 | 5L | Maximum Trap Mode: 4000kg/h; Maximum Pump Mode: 1100kg/h |

| APT14HC | 8L | Maximum Trap Mode: 9000kg/h; Maximum Pump Mode: 2800kg/h |

| APT14SHC | 8L | Maximum Trap Mode: 9000kg/h; Maximum Pump Mode: 2800kg/h |

Back Pressure (BP) = (Height H × 0.0981) + Condensate Pipeline Pressure (P) + Downstream Pipeline Flow Friction Resistance (Pf)

The following parameters are required when selecting a steam trap pump:

| Spare Part Name | Included Part Numbers (Refer to Product Diagram) | Applicable Models | Notes |

|---|---|---|---|

| Pump Cover Assembly | 1, 2, 5-25 | All Models | Includes all required maintenance accessories |

| Pump Cover Gasket | 2 | All Models | Available as individual spare part |

| Inlet Check Valve | 2, 12 | All Models | Includes seals and accessories |

| Spring and Push Rod | 2, 14, 24 | All Models | Stainless steel material, supplied as set |

| Float Ball | 2, 5, 6, 7 | All Models | Stainless steel material |

| Trap and Outlet Check Valve | 2, 8, 9, 10, 21, 22, 23 | APT14 | Includes two-stage trap assembly |

| Trap and Outlet Check Valve | 2, 8, 9, 21, 22, 23 | APT14HC, APT14SHC | Excludes part No. 10 |

| Inlet/Exhaust Valve Plug and Seat Assembly | 2, 16, 17, 18, 19, 27 | All Models | Includes split pins, washers, gaskets, etc. |

| Outlet Check Valve DCV10 | - | APT14HC, APT14SHC | Refer to technical data TI-P601-32 |

Spirax Sarco Automatic Steam Trap Pump APT14, DN40×DN25, Flange Connection (EN1092 PN16), with Threaded Connection (BSP) Motive Steam Port

Explore similar products in our catalog